Wiki

Clone wikimofem-joseph / Brick slice

###Brick Slice###

Keywords: Crack Propagation, Fracture, High-Order Approximation, Automatic Mesh Refinement

Problem description

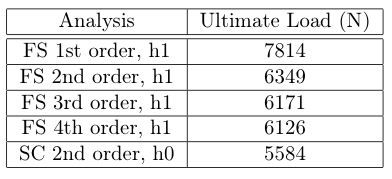

A graphite brick slice is placed in a test rig as indicated in Figure 1 below with a force applied to the crosshead. We want to calculate the propagation of the crack through the brick slice and to examine the load-displacement response.

Figure 1. Brick slice in loading rig

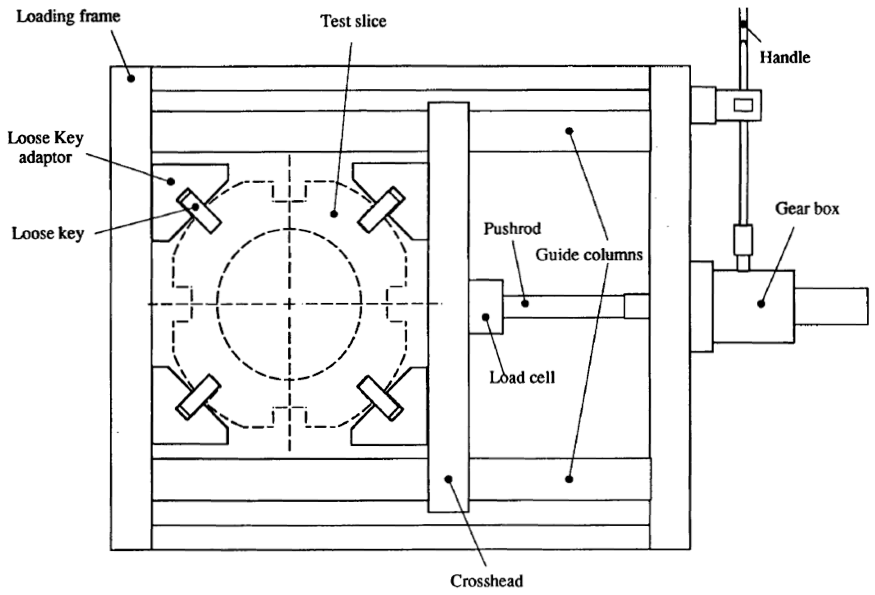

Figure 2. Brick slice dimensions

Files

The CUBIT journal file required to generate the models can be downloaded from here:

The files are also located under /mofem_install/mofem/benchmarks/brick_slice/ in the MoFEM source and build directories.

Geometry

Considering figure 2 above, the brick slice is 25 mm thick, has an inner radius of 263.25 mm and an outer radius of 459.8 mm. The width of the interstatial keyway is 32.95 mm and the width of the loose keyway is 20.25 mm with all keyways 37 mm deep.

Material properties

Young's modulus E = 1.09 N/mm²

Poisson's ratio v = 0.2

Griffith energy g = 2.3e-5 N/mm

For convenience, the values of E and g above have been scaled by e-4. This is to achieve a Young's modulus of approximately 1 N/mm² which will simplify the computational performance.

Loads

The reference load, which is scaled, applied to a small surface (2400 mm²) on the crosshead is equal to 6.2e-4 N.

Finite Element Model

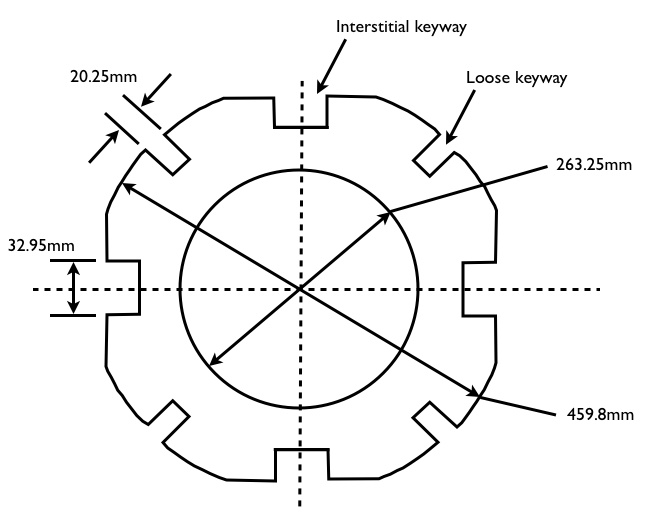

The finite element model comprises of the graphite brick slice, the loose key adaptors and the crosshead and loading cell only. The model consists of a relatively coarse uniform mesh of 4-node tetrahedral elements as shown in Figure 3. We will use automatically different orders of approximation and levels of mesh refinement to improve the solution. In addition to the load shown above, we apply displacement constraints to prevent rigid body motions (see CUBIT journal files).

The crack is defined geometrically in CUBIT by a single surface. It is worthwhile to note that the visible cylindrical cutout around the crack is only used to construct the crack geometry and optionally give better mesh control around the crack. The crack tips and crack surface are specified by custom sidesets.

Figure 3. Geometry (left) and mesh (right)

Analysis procedure

The analysis is run in two stages. The first stage uses a script to calculate the Griffith forces for 1st (linear) to 4th (quartic) order 4-node elements. For each order, analyses with 1 level of automatic refinement are run. All analyses were run on the ARCHIE_WeSt high performance computer using 12 processors with the FGMRES (Flexible Generalized Minimal Residual Method) Krylov solver for systems of linear equations and the LU preconditioner. The first script can be executed using:

$ ./convergence_study.sh -f brick_slice.cub -l -1 -g 2.3e-5 -o 0,1,2,3,4 -r 1 -p $NPROC

If desired, the Mode I stress intensity factor ( ) can be calculated directly from the output Griffith forces, see the Analysis procedure section of the plate with horizontal crack benchmark.

) can be calculated directly from the output Griffith forces, see the Analysis procedure section of the plate with horizontal crack benchmark.

The second stage uses a script to calculate, over a prescribed number of steps, the propagation of the crack for a specified approximation order and level of mesh refinement, using the resultant Griffith forces from the first stage. All analyses were run on the ARCHIE_WeSt high performance computer using 12 processors with the FGMRES (Flexible Generalized Minimal Residual Method) Krylov solver for systems of linear equations and the LU preconditioner. To calculate the propagation of the crack for the 2nd (quadratic) order with 1 level of automatic mesh refinement, for example, the script can be executed using:

$ ./arc_length.sh -f $DIRNAME/out_spatial_2_0.h5m -a 0.5 -n 500 -g 2.3e-5 -t 1e-8 -i 12 -p $NPROC

Results

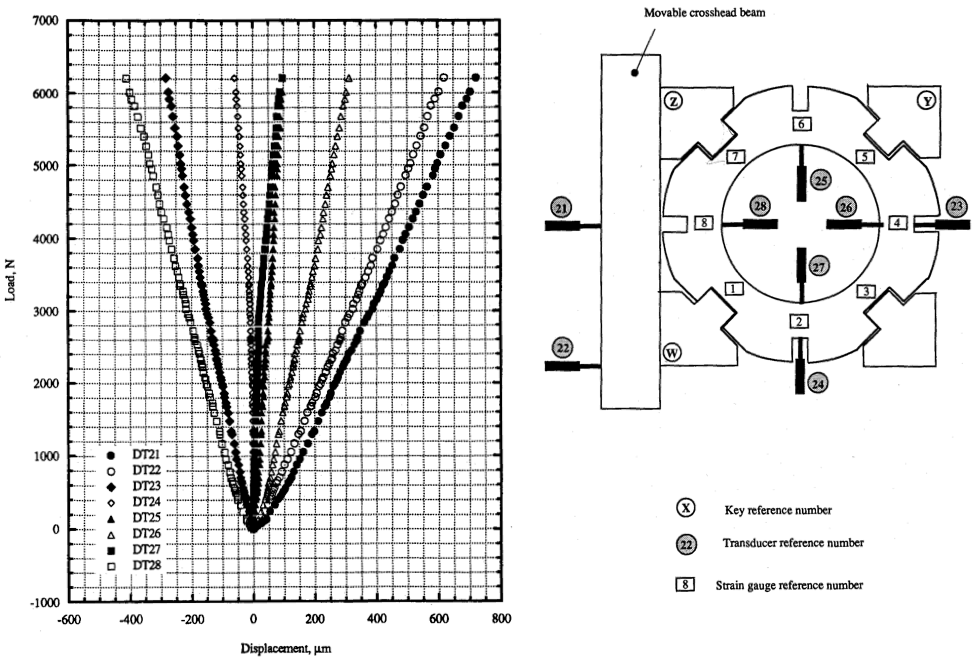

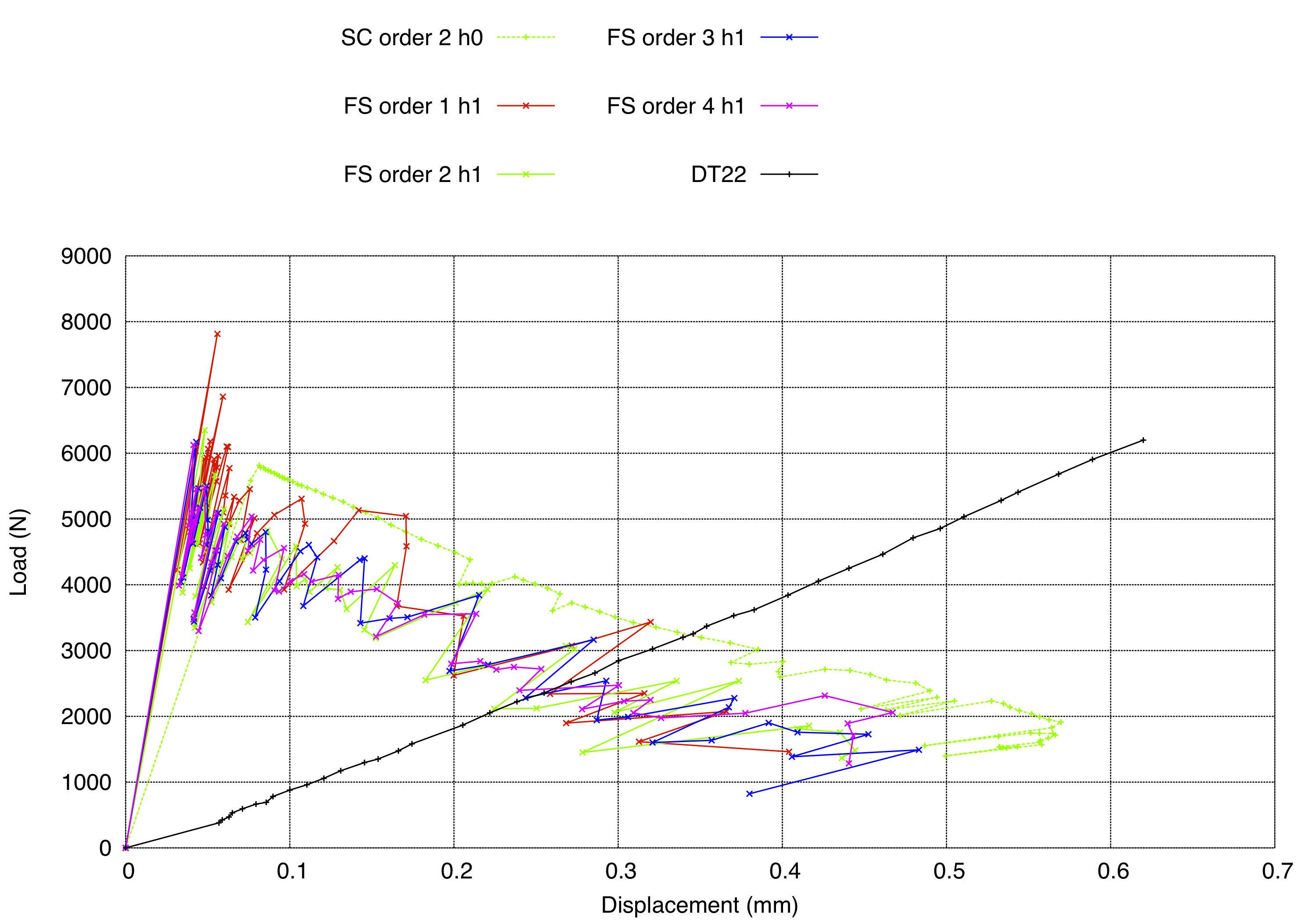

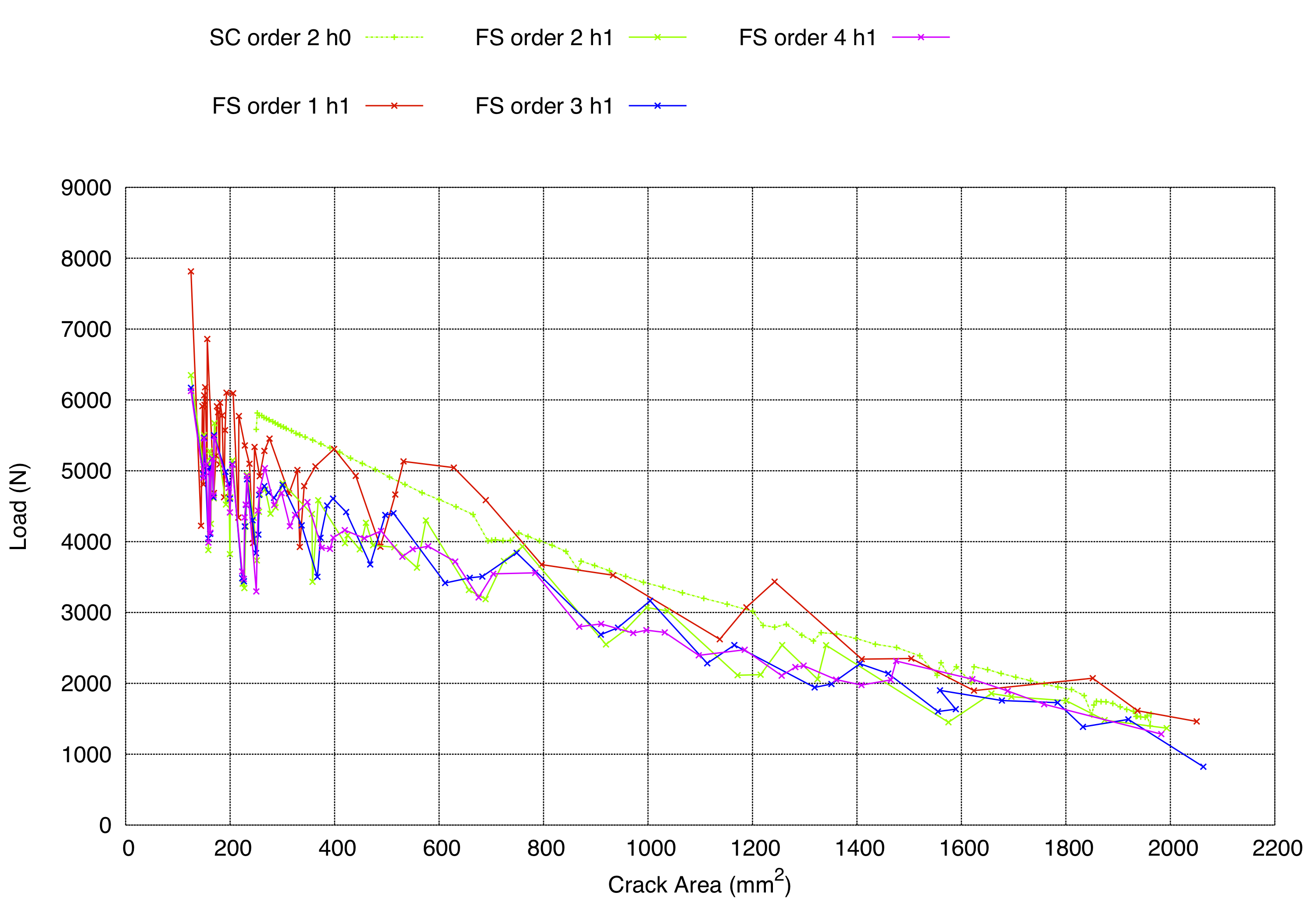

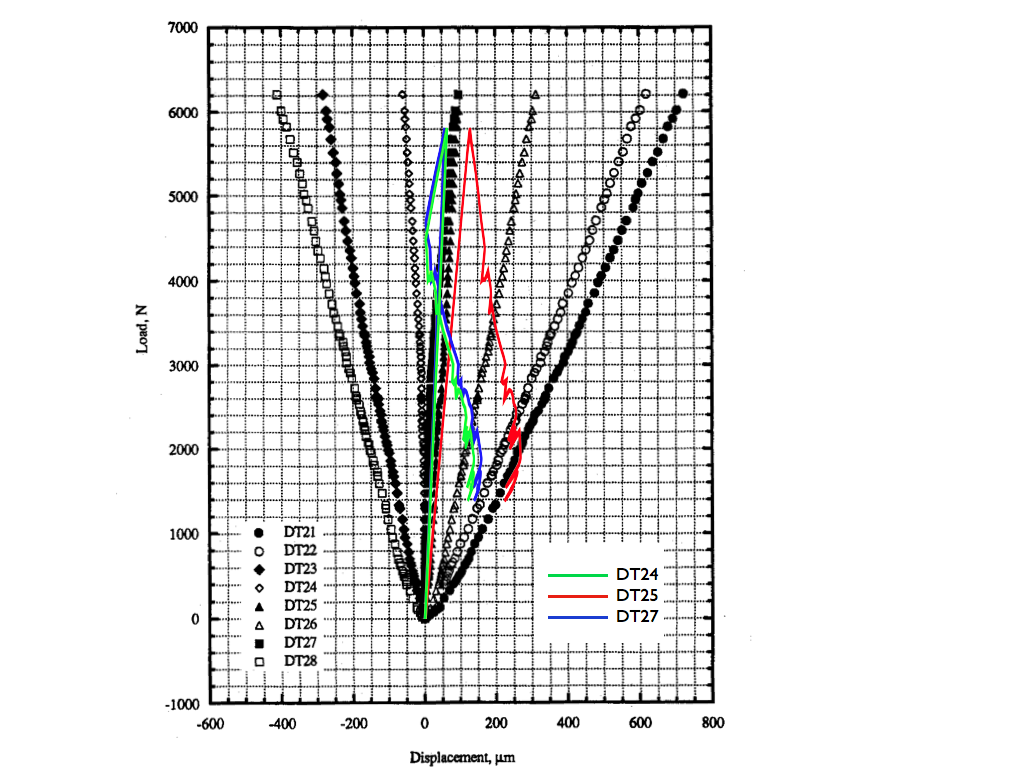

Figure 4 shows the deformed shape of the graphite brick slice for the 2nd order solution with no levels of mesh refinement using the smooth crack propagation with flip analysis MOFEM v0.2. Figure 5 shows the deformed shape of the graphite brick slice for the 3rd order solution with one level of mesh refinement using face splitting analysis in MOFEM v0.1. The results from all analyses are illustrated in Figures 7 and 8. These show the horizontal displacement of the crosshead against load, and crack area against load for each analysis. Added to the load-displacement graph is the response as recorded in experimental testing. Examining Figure65, the curve DT22 is the most appropriate against which to compare.

Figure 4. Deformed shape for 2nd order approximation with no levels of automatic mesh refinement using smooth crack propagation with flip analysis in MoFEM v0.2

Figure 5. Deformed shape for 3rd order approximation with one level of automatic mesh refinement using and crack propagation with face splitting analysis in MoFEM v0.1

Notice the difference in crack propagation, the heavily distorted elements (left) and the refinement of the mesh (right) as the crack propagates through the brick slice. The script file required to extract the desired data (from log files) and plot the graphs can be downloaded from here:

The files are also located under /benchmarks/brick_slice in the MoFEM source and build directories. The graphs can be plotted using:

$ ./plot_graphs.sh -o 1,2,3,4 -r 1 -ent 1612 -dim 1 -s 1e4*2400*2.6e-4

where -s is a scaling factor which is the product of the applied load (see CUBIT journal file), the area over which the load is applied and the inverse of the scaling factor applied to E and g. This scaling is highly important to ensure correct results. Log files must be placed into a directory named log_files and log files must follow the naming convention log_ORDER_REF-LEVEL, with the plot file located one level above log_files. For more information on plotting, see Plotting information.

Figure 6. Experimental results for load-displacement at various locations

Figure 7. Displacement versus load for smooth crack propagation with flip (SC) and crack propagation with face splitting (FS); note points have been removed for steps that did not converge

Figure 8. Crack area versus load for smooth crack propagation with flip (SC) and crack propagation with face splitting (FS); note points have been removed for steps that did not converge

Discussion and Further Results

- Initially examining the horizontal displacement and comparing to DT22 illustrates that the stiffness is different.

- This is due to:

- Unknown stiffness of the crosshead.

- Unknown stiffness of the loading frame in experiment.

- Initial loading in the experiment would remove any gaps between the brick slice and loose key adaptors thus effecting the recorded horizontal displacement.

- Therefore, the vertical displacement at locations DT24, DT25 and DT27 will now be examined because:

- There will be little or no effect from the stiffness of the crosshead.

- Initial loading in the experiment would remove any gaps between the brick slice and loose key adaptors but this will not effect the recorded vertical displacement as the load is applied horizontally.

- Extracting the data from ParaView for points close to the locations of DT24, DT25 and DT27, and comparing to the experimental data, see Figure 9, shows a very good correlation.

Figure 9. Displacement versus load for 2nd order with no levels of automatic mesh refinement using smooth crack propagation with flip (SC), overlaid with the experimental results.

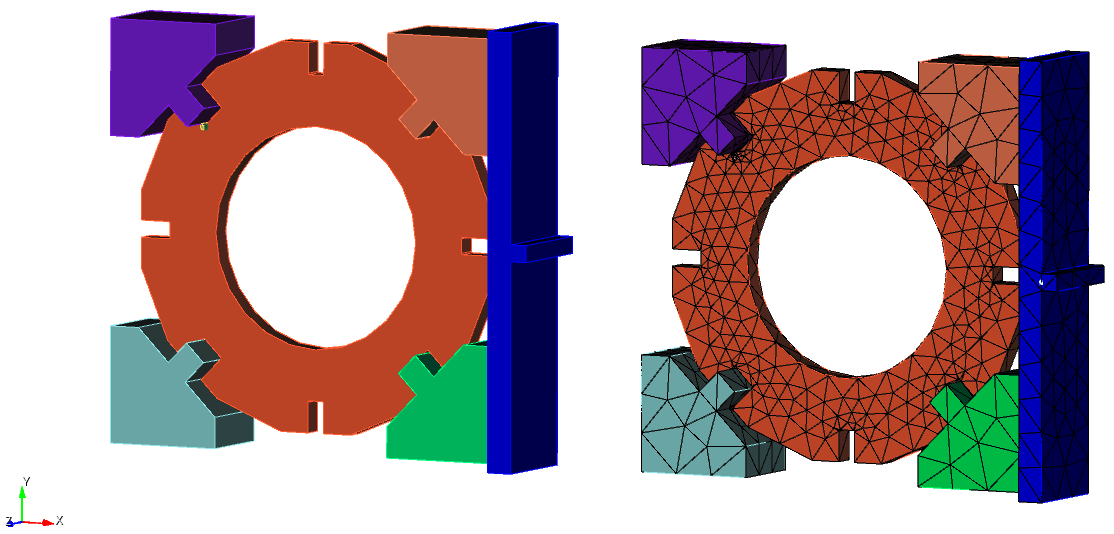

The failure loads for each analysis were recorded as follows:

Table 1. Ultimate Loads

Acknowledgements

Results were obtained using the EPSRC funded ARCHIE-WeSt High Performance Computer (www.archie-west.ac.uk). EPSRC grant no. EP/K000586/1

References

- Three‐dimensional brittle fracture: configurational‐force‐driven crack propagation, Ł Kaczmarczyk, MM Nezhad, C Pearce, International Journal for Numerical Methods in Engineering 97 (7) 531-550

- Created by Ross Mackenzie

- any difficulties or suggestions email cmatgu@googlegroups.com

Updated